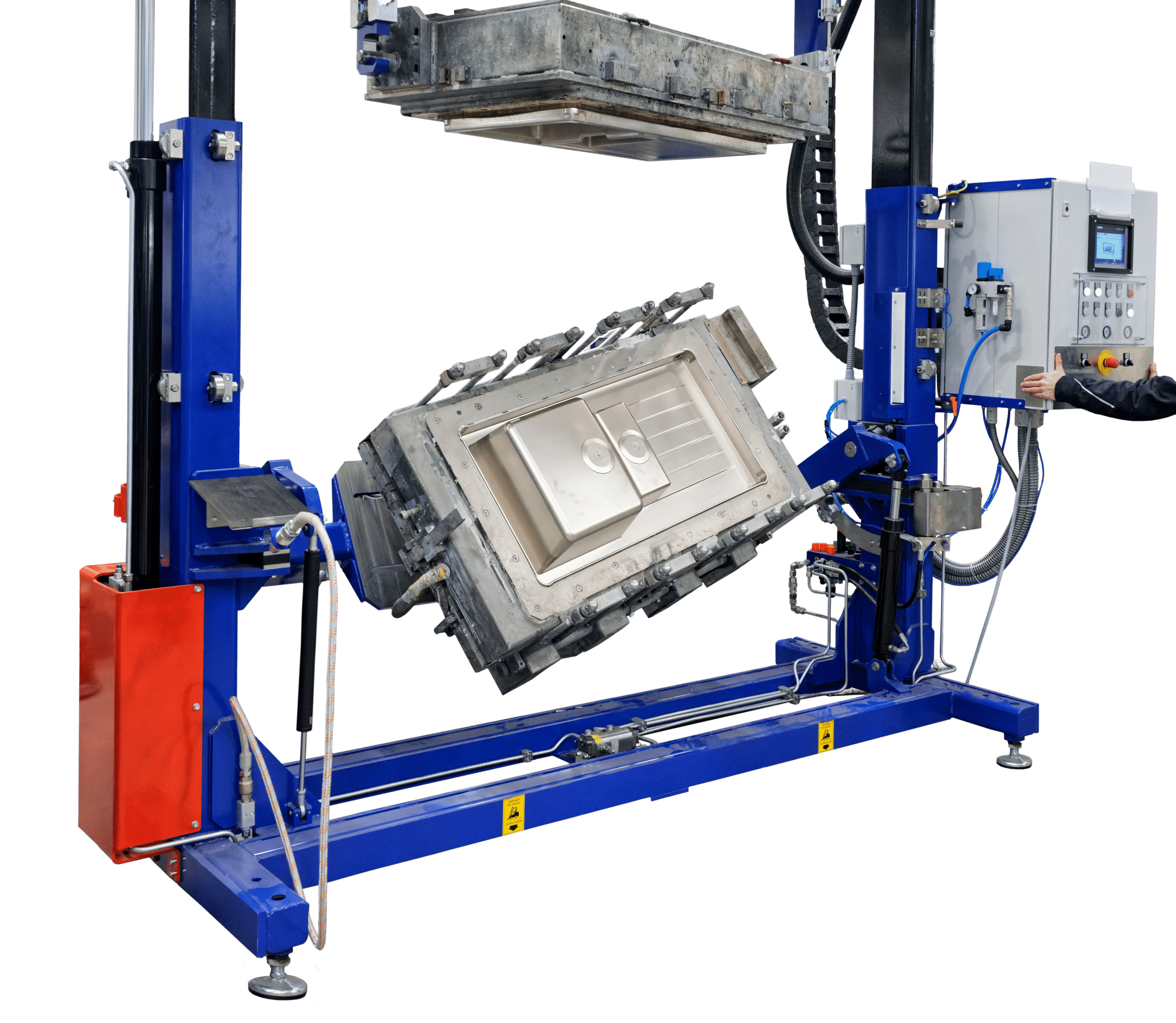

Moulds weighing up to 3.5 tons are used in this system. The actual casting mold is mounted on the base plate of the swivel mold holder. The mold can be precisely positioned and then screwed into place using the slotted holes in the base plate. In the initial state, the two-part mold is closed and tilted 90° to the side via the swivel mold holder. When tilted, the mold can be filled manually by the operator. After filling, the automatic program of the system is started by pressing a start button. While the upper crossbeam is responsible for lifting the upper shell of the mold, the lower swivel device ensures ergonomic removal of the finished component.

Technical Specifications

The mould carriers are also available in a fully electric version, which has been developed using state-of-the-art technology.

The lifting movement is carried out by means of a three-phase motor and gearbox, the swivel movement by means of a servo motor and gearbox. This enables infinitely variable adjustment of the swivel movement and adaptation to the respective geometry of the mould to be cast.

The lifting movement is carried out with high precision via linear guides. The swivel movement using a servo motor also enables a negative swivel movement.

Advantages

- hydraulically or electrically driven variants available

- Various sizes for molds with up to 3.5 tons

- Negative swivel movement possible with electric version

- State-of-the-art Siemens control system

- Optional remote access