Steel Construction

Steel Construction Assembly

Assembly

Control cabinet construction /

wiring Planning

Planning

Recurring

inspections Consulting

Consulting

Electrical design /

Programming Commissioning

Commissioning

Process

development Construction

Construction CNC Manufacturing

CNC Manufacturing Image analysis

Image analysis

Services

Quality made in Germany

We have not specialized in any specific product or technology area, but instead, we deliberately focus on continuously developing new processes for our customers. Additionally, we continuously expand our range of expertise to design your system from a single source.

IPROTEC GmbH originated in the glass industry, and our capabilities are especially evident through our close collaboration with Zwiesel Glas AG. For the world leader in stem glass for the upscale hotel and gastronomy sectors, we have repeatedly set technological milestones with new, innovative production technologies.

This results in comprehensive system concepts for special machine construction, tailored to your requirements in every aspect and featuring a high degree of innovation.

Workpiece analysis

In the course of increasing automation, image processing has become an indispensable tool for quality assurance.

Our specialists support you at every step of such a project, from specification, laboratory tests, development of an appropriate optical setup, system construction, software development, to commissioning and later support.

One of our key strengths is the development and construction of optical inspection systems from a single source, covering optics, software development, and system construction. Even during operation, we are able to quickly and directly provide customers with competent support for any questions or issues.

- Extensive expertise in optics and camera technology, development of customized solutions for lighting, triggering, and communication.

- Development of the inspection solution based on industry standards, with the option to enhance algorithms with custom solutions as needed, up to a complete application.

- Creation of user-friendly interfaces, ensuring short changeover times during product transitions.

- In-house development ensures long-term support for the solutions provided.

- Integration of solutions into the customer's existing infrastructure.

Process optimization

After the initial commissioning, the real work often begins for our experienced process developers:

in collaboration with the customer, we strive to achieve an optimal production process.

We raise awareness about the specific process and analyze it thoroughly.

We set goals and optimize the process. Worldwide.

Our years of experience support us in this endeavor.

- • Wide range of applications

- • Worldwide deployment

- • Production support over extended periods

- • Execution of hot commissioning

Service

Plant maintenance in industrial environments, maintenance of facilities and machines of all kinds, and ensuring minimal downtime on production lines around the clock are just a few of the tasks handled by our diverse team of electrical specialists and engineers.

- • Support for production facilities in an industrial environment.

- • Support for glass furnaces and channels in an industrial environment.

- • Support for laser systems in an industrial environment.

- • 24/7 availability and rapid support through remote access.

- • Highly experienced and qualified deployment team for quick and solution-oriented approaches.

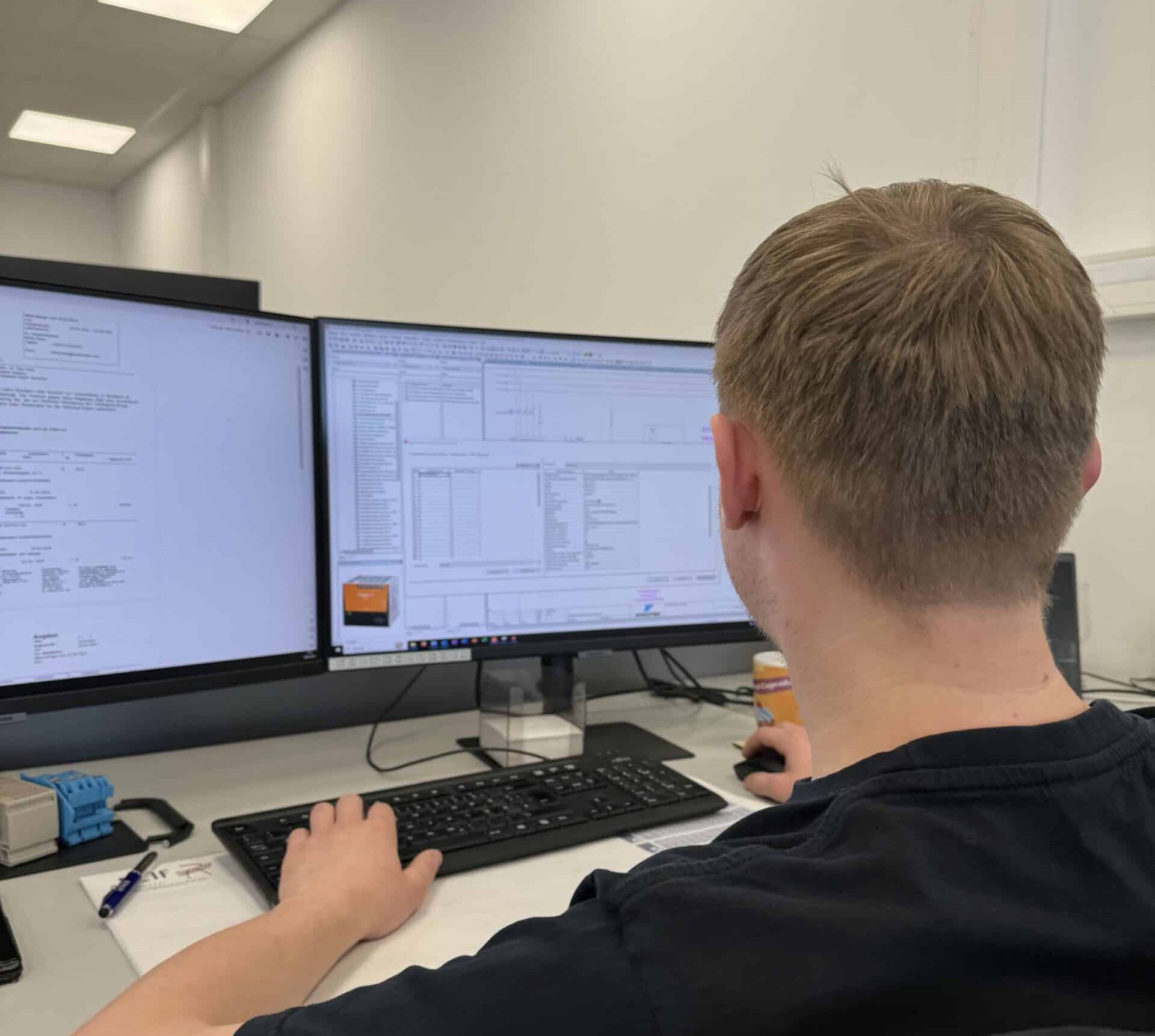

Construction

The construction documents are the foundation for every technical system or machine.

For this reason, it is especially important to us that these documents are well thought out and consistent from A to Z.

Only in this way can we ensure that your project is implemented optimally.

Our highly qualified design team works closely with the customer throughout the planning phase.

We place great importance on your satisfaction as a customer and encourage you to share your suggestions and wishes with us at any time.

- 3D-Solid Works

- 2D-AutoCAD

- Simulation and analysis capabilities in a 3D system

- Extensive construction experience

- Close coordination with manufacturing, control construction, and installation in-house

Electrical construction

Where electricity is used, it must be distributed, controlled, and regulated.

Control cabinets and control systems take on this task.

Due to their high functional significance, it is particularly important that they are precisely tailored to individual requirements.

We plan, develop, and create the control technology that fully meets these tasks in every respect.

Our years of experience in this field of electrical engineering make us a competent partner.

- • Project planning and development of hardware concepts for special machines and systems

- • Creation of all hardware documentation based on EPLAN P8 (circuit diagrams, parts lists, evaluations, etc.)

- • Creation of documentation

- • Support for control cabinet construction and interface for internal and external contacts

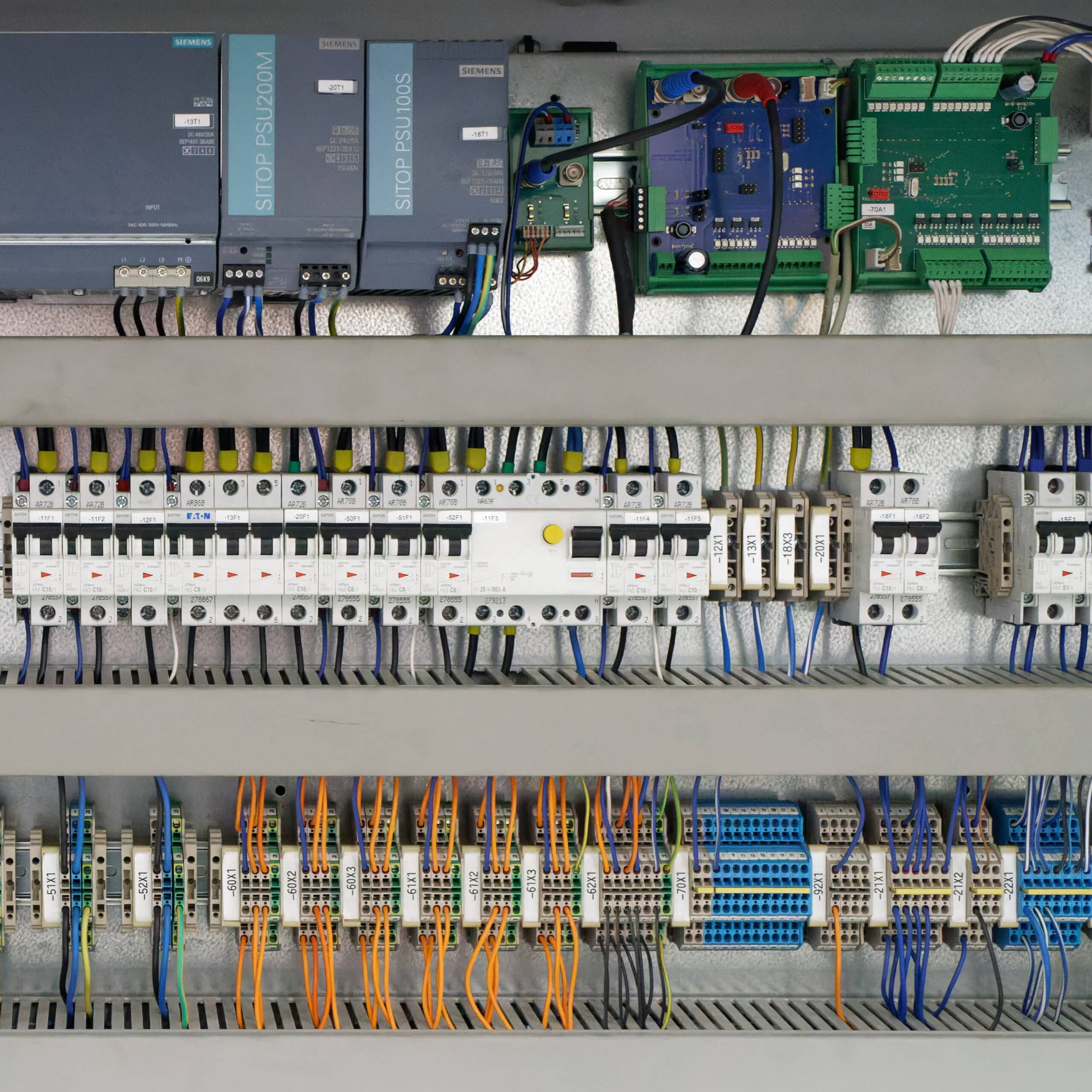

Control cabinet construction

We manufacture control and switching systems for many areas across various industries.

Our strength lies in the quality-oriented, timely, and flexible production of control cabinets, especially for custom and complex projects.

Continuous planning and adherence to each step of the process ensure quick and smooth completion.

From building cable routes to connecting all sensors, motors, and actuators, up to the I/O check with pre-commissioning, you are in the best hands with us.

- • Execution of mechanical work on mounting plates and enclosures

- • Wiring of electrical assemblies and control cabinets

- • Wiring of complex electrical systems according to circuit diagrams

- • Conducting tests and commissioning of systems in-house and at the customer's site

Programming

The visualization as an interface to the operator provides feedback on the status of the system and assists in process optimization. The control itself monitors the process flow and is responsible for the safety of both people and machines. As a certified Siemens Solution Partner focused on factory automation and motion control, we create and maintain a solution tailored to your needs.

- • Creating the software solution from safety integration to HMI

- • Integration of the system into the production environment

- • Certified Siemens Solution Partner for Factory Automation

- • Certified Siemens Solution Partner for Motion Control

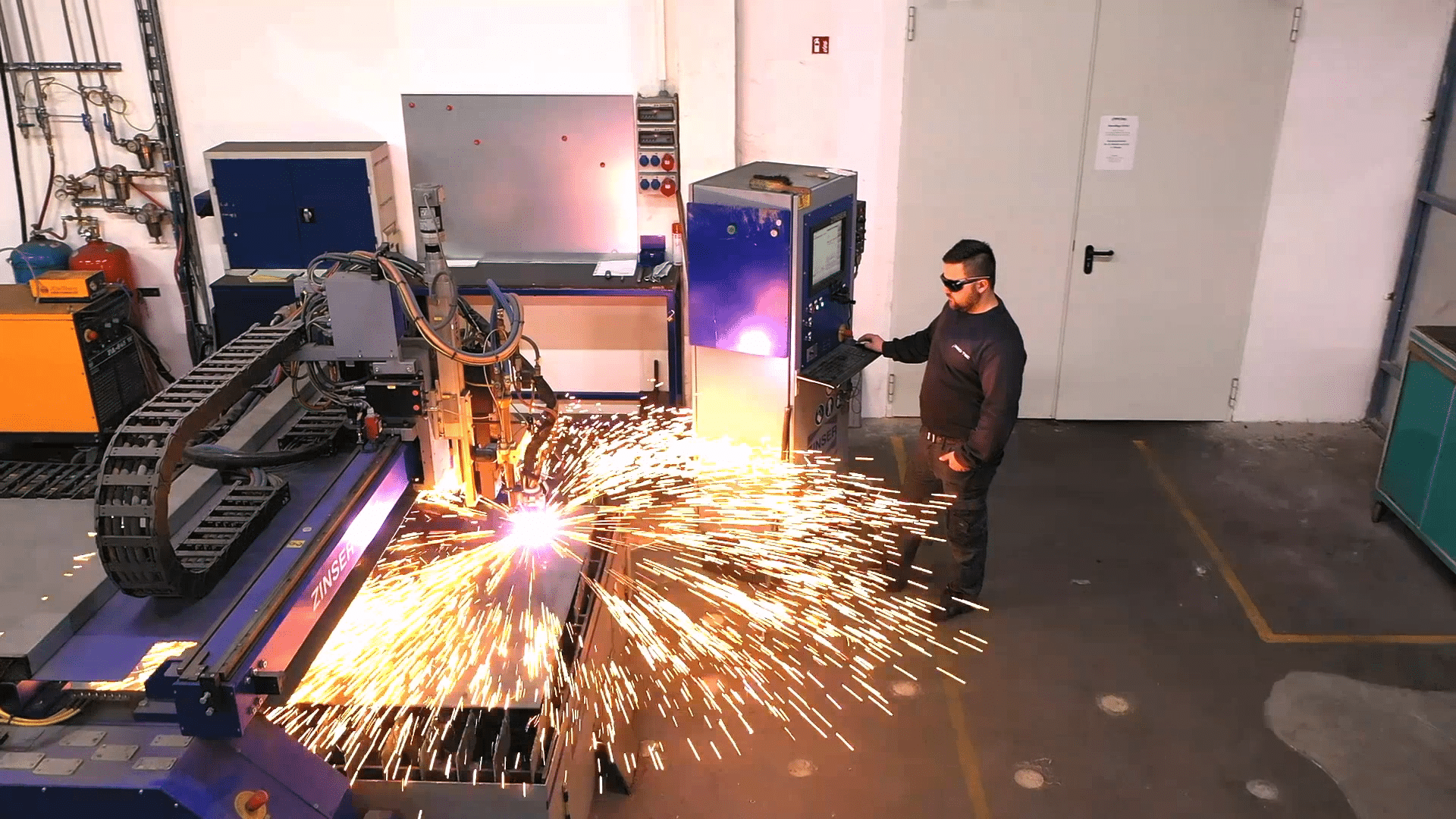

CNC manufacturing

Due to our high manufacturing depth, we are able to produce individual parts of your system largely in-house.

For peak production times, we strategically rely on trusted regional partners with whom we have successfully collaborated for years.

This allows us to ensure that communication paths are short and the results are optimal.

Our machine park, equipped with lathes, milling, and drilling machines, ensures flexibility and efficiency in the manufacturing of workpieces and machine components, both as prototypes and in series. We are technologically up to date, execute orders on schedule, and can also handle order peaks.

Our CNC machines are programmed by our specially trained staff using modern CAD/CAM workstations.

- CNC milling: 2x DMG DMU 60 monoBlock, Hurco VMX40, Hurco VMX42SR, Hedelius Tiltenta 6-2300

- CNC turning: DMG CTX 420 linear, DMG NEF 600, DMG ECOTurn 450

- Other machines: surface grinding machine, start hole drilling machine, band saws, bending machine, sheet metal shears

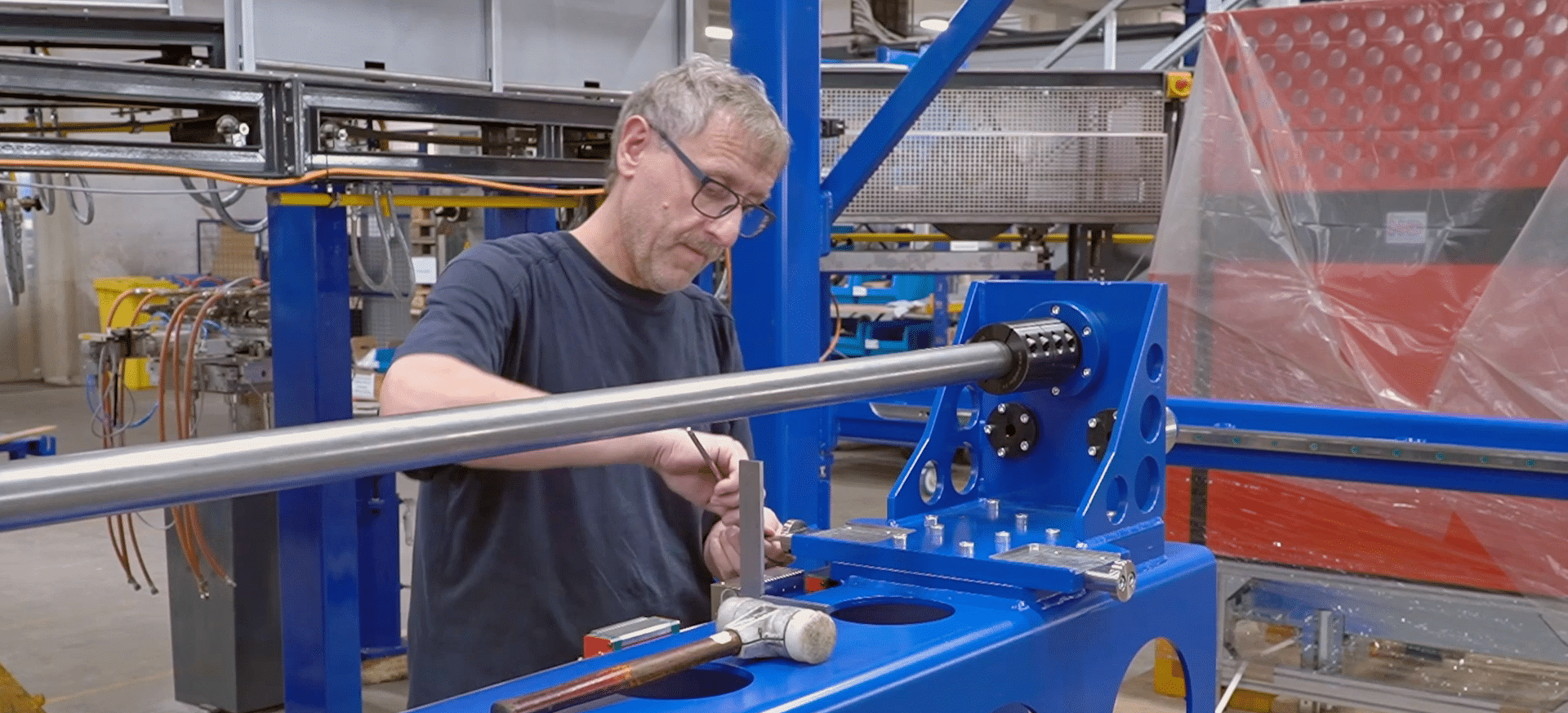

Installation

The highest level of expertise is also reflected in our assembly.

Whether in drive technology, linear technology, or pneumatics, our assemblers possess extensive know-how.

Starting with pre-assemblies, the individual components are then assembled into the overall system.

It is also possible for only your components to be pre-assembled by our technicians, which we can then send to you.

To keep our team up to date, it is a matter of course for us that our employees participate in various training courses every year.

- • Installations in drive technology (including direct drives)

- • Linear technology

- • Conveyor technology

- • Pneumatics

- • All types of industrial installations for machines and systems.

Commissioning

During commissioning, our systems come to life.

This usually takes place in our spaciously equipped assembly hall but can sometimes also occur directly at the customer’s site.

Here, the systems are thoroughly tested to ensure that your system can be delivered to you without errors, even if it is a prototype or a unique piece.

- • Quality assurance through the four-eyes principle at the end of commissioning

- • Early assurance of required functions for the fastest possible system integration at the customer's site

- • Compliance with the highest quality standards in special machine construction

Steel and metal construction, welding solutions

We are capable of implementing a wide range of highly complex tasks in steel and metal construction.

Certified welding specialists manufacture components from various metallic materials.

Especially with materials in the high-temperature range, we can reliably meet your requirements due to our years of experience.

We are specialists in the production of highly wear-resistant surfaces for conveyor and material handling systems!

- • Manufacturing of steel construction support structures, including installations according to DIN EN 1090 EXC 2, such as machine platforms and staircases.

- • Manufacturing of components as a certified welding specialist according to EN ISO 3834-3, such as screw conveyors, including hardfacing and applications with special alloys.

- • Manufacturing of components according to the certified welding procedure of the Pressure Equipment Directive ISO 15614-1, AD2000-HP2/1 EN 13445, such as containers in pneumatic conveying technology.

- • High-temperature components such as burner nozzles and heads or installations in high-temperature furnaces and exhaust systems.