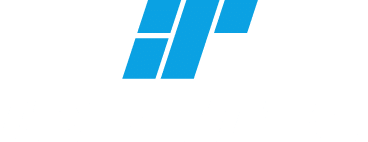

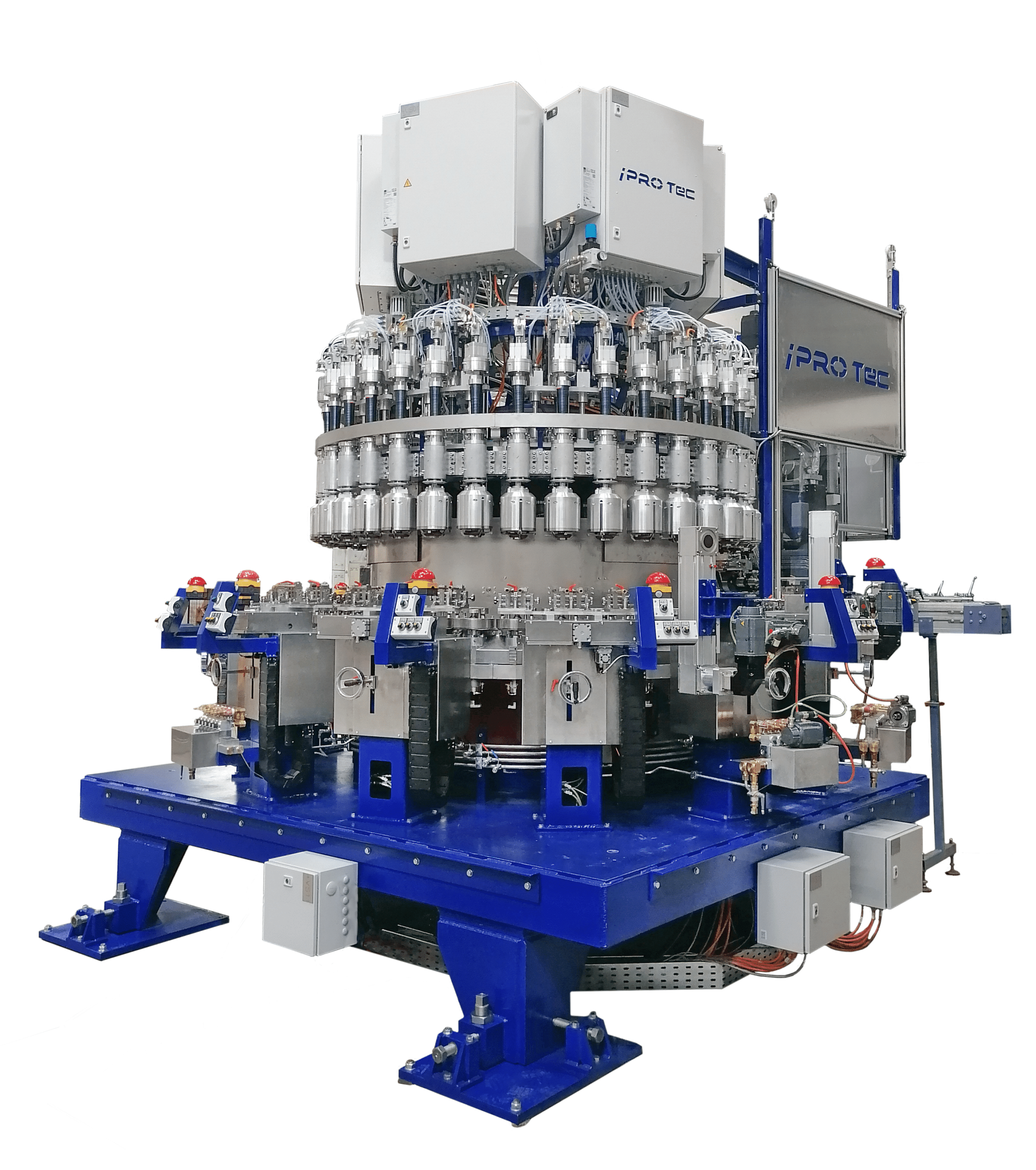

STEMWARE

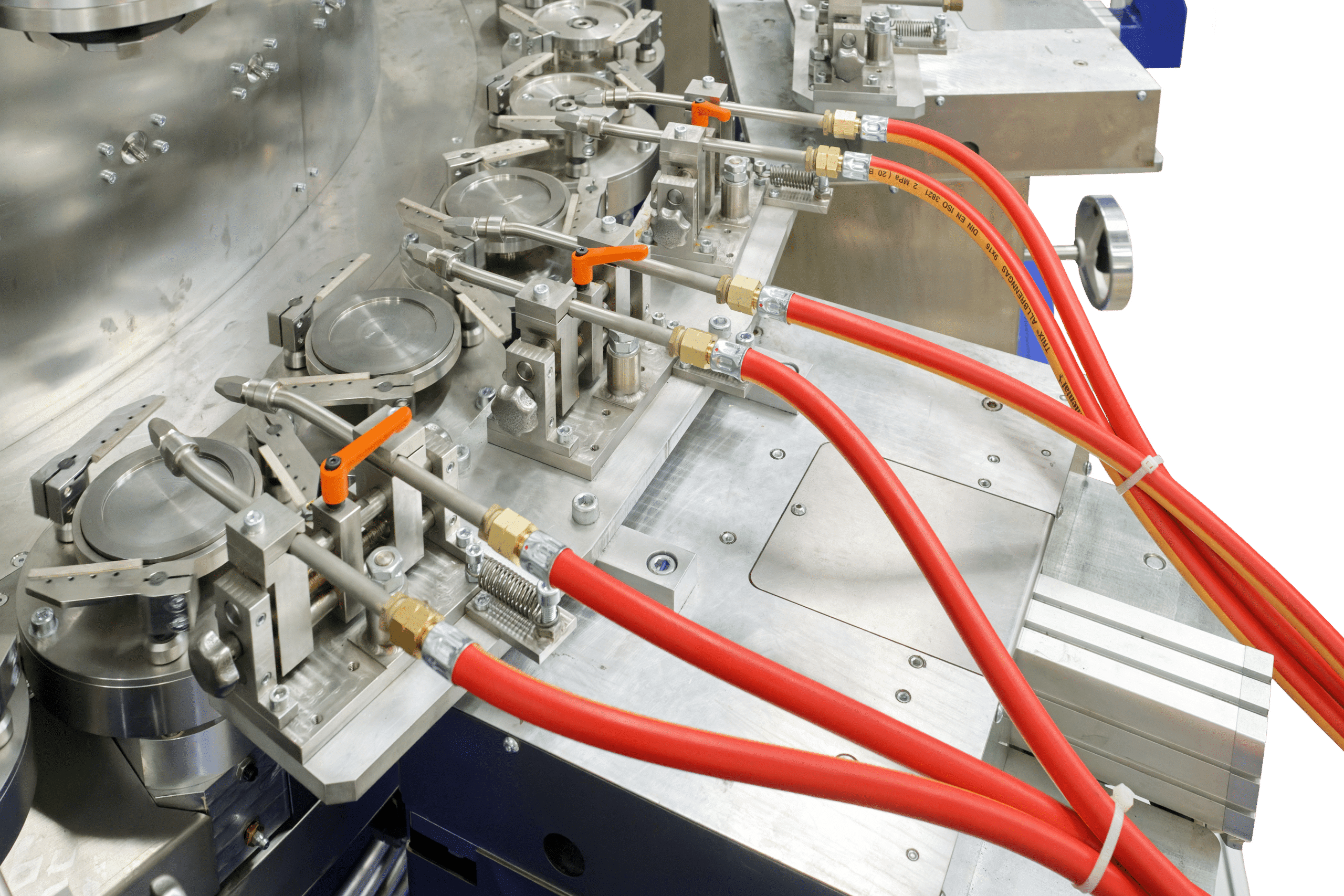

SEALING – STRETCHING

– POLISHING MACHINE

A unique and multifunctional solution in the tableware

market with different operation modes:

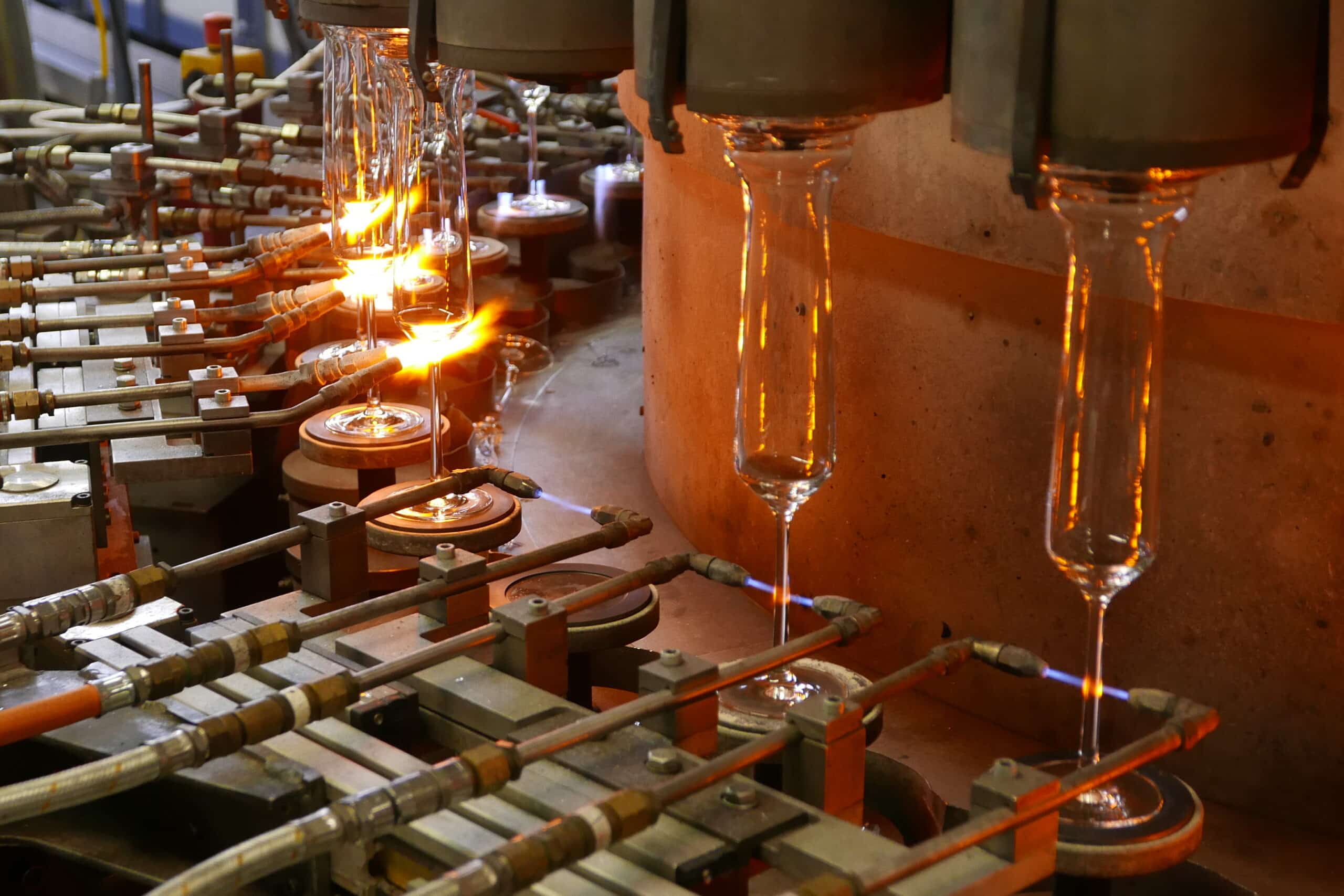

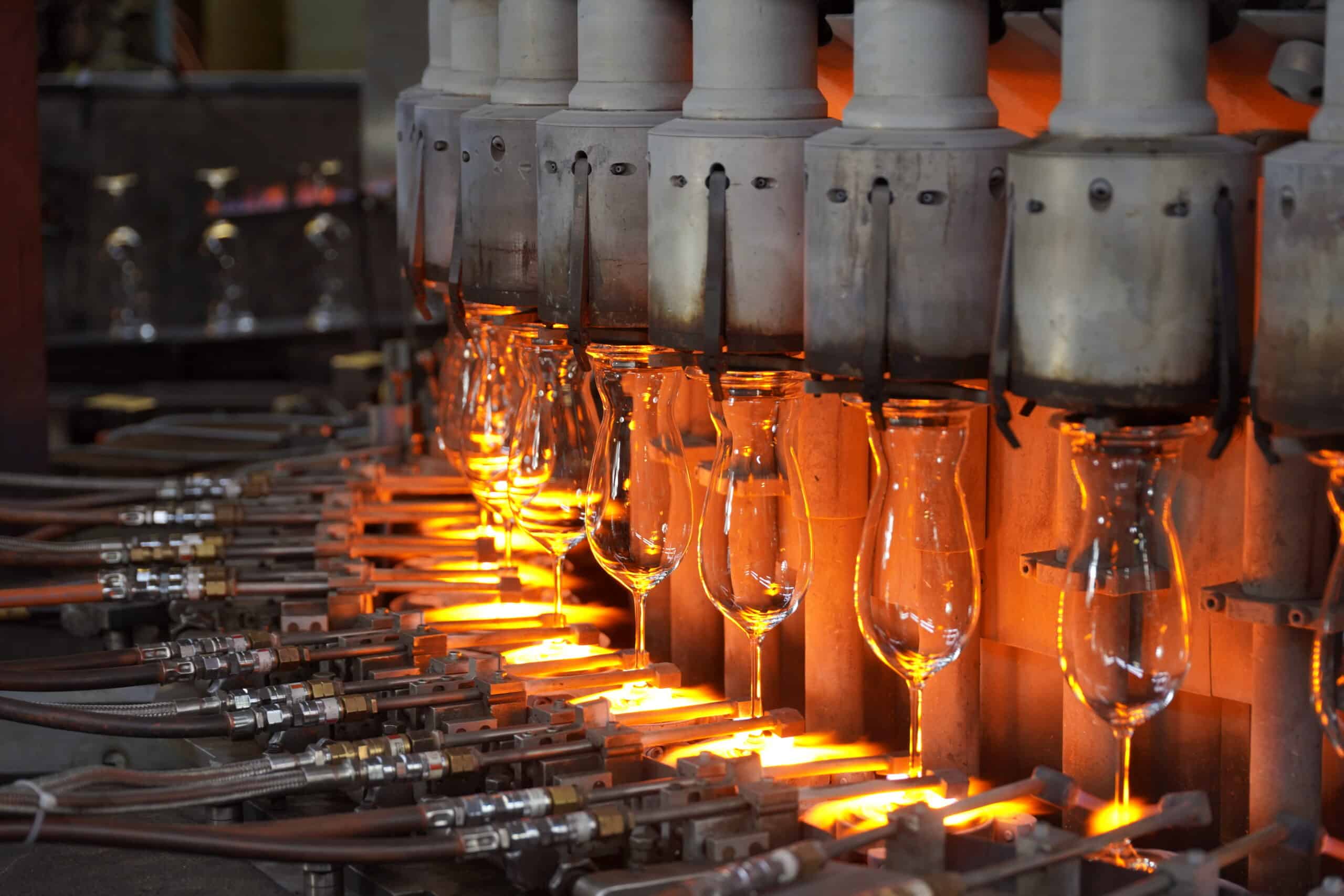

STEMWARE SEAM POLISHING

✓ bottom seam

✓ stem seam

✓ ring seam (stem-bottom)

✓ transition seam (bowl-stem)

✓ ring seam around the base plate

STEMWARE SEALING

STEMWARE STRETCHING

Technical Specifications

Dimensions:

Advantages

- ✓ linear loading and unloading unit with triple gripper head

- ✓ from 24 to 60 stations

- ✓ speed up to 60 pcs/min

- ✓ compact design

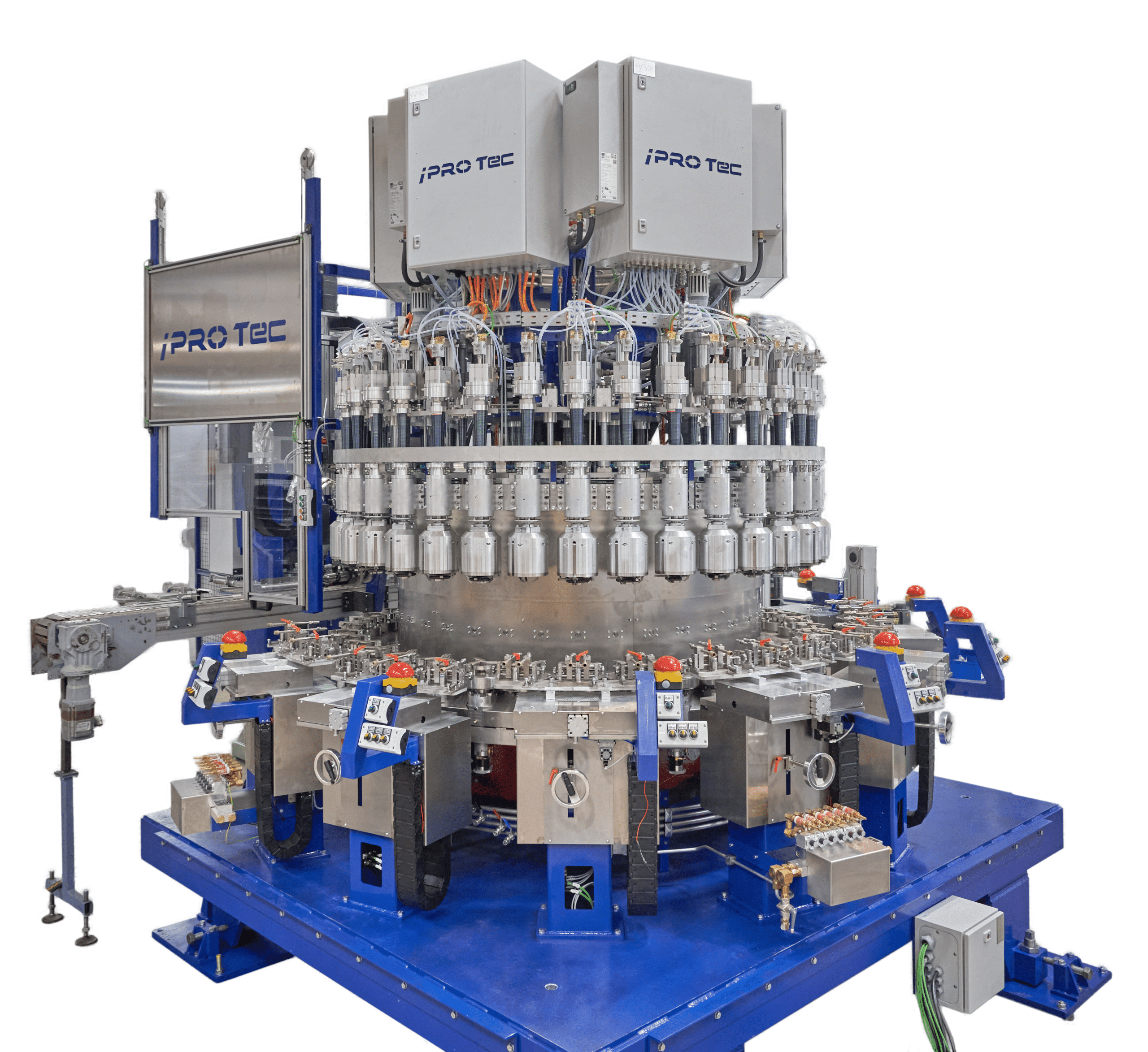

- ✓ burner tracking system with usage of natural gas / oxygen or hydrogen / oxygen

- ✓ low energy consumption due to pre-mix technology for burners

- ✓ proven adjustment systems for burners to polish all critical areas

- ✓ decades of experience in the construction of polishing burners

- ✓ servo controlled independent seam orientation of each item per station

- ✓ adjustable stretching stroke by servo motor

- ✓ easy and fast job change

- ✓ operator friendly

- ✓ maximum reliability

Tobias Bredl

Your expert for Glassware Machinery

+49 9922 98 442

tobias.bredl@iprotec-gmbh.com