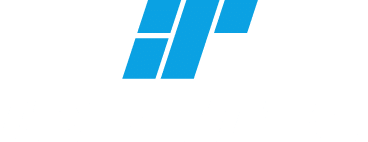

IPROTEC offers the latest generation of blowing machines

with the highest production rate and quality.

The long-term partnership with Zwiesel Glas has enabled IPROTEC to optimize the production process continuously, with the result that many valuable features

have been developed, such as pre-pressing with reduced moil weight or servo

tracking system for fire polishing. IPROTEC blowing machines are mainly dedicated

to premium articles (Borosilicate / Opal / Crystal / Soda-Lime).

Technical Specifications

Basic dimensions (L x B x H): up to 7,5 x 7,2 x 5,3 m

Pitch circle diameter: up to 5,0 m

Number of stations: 1-32

Weight: up to 50 t

Advantages

- ✓ blow-blow-process & press-and-blow-process

- ✓ production speed up to 60 pcs/min

- ✓ direct gob feeding or gob feeding via chute

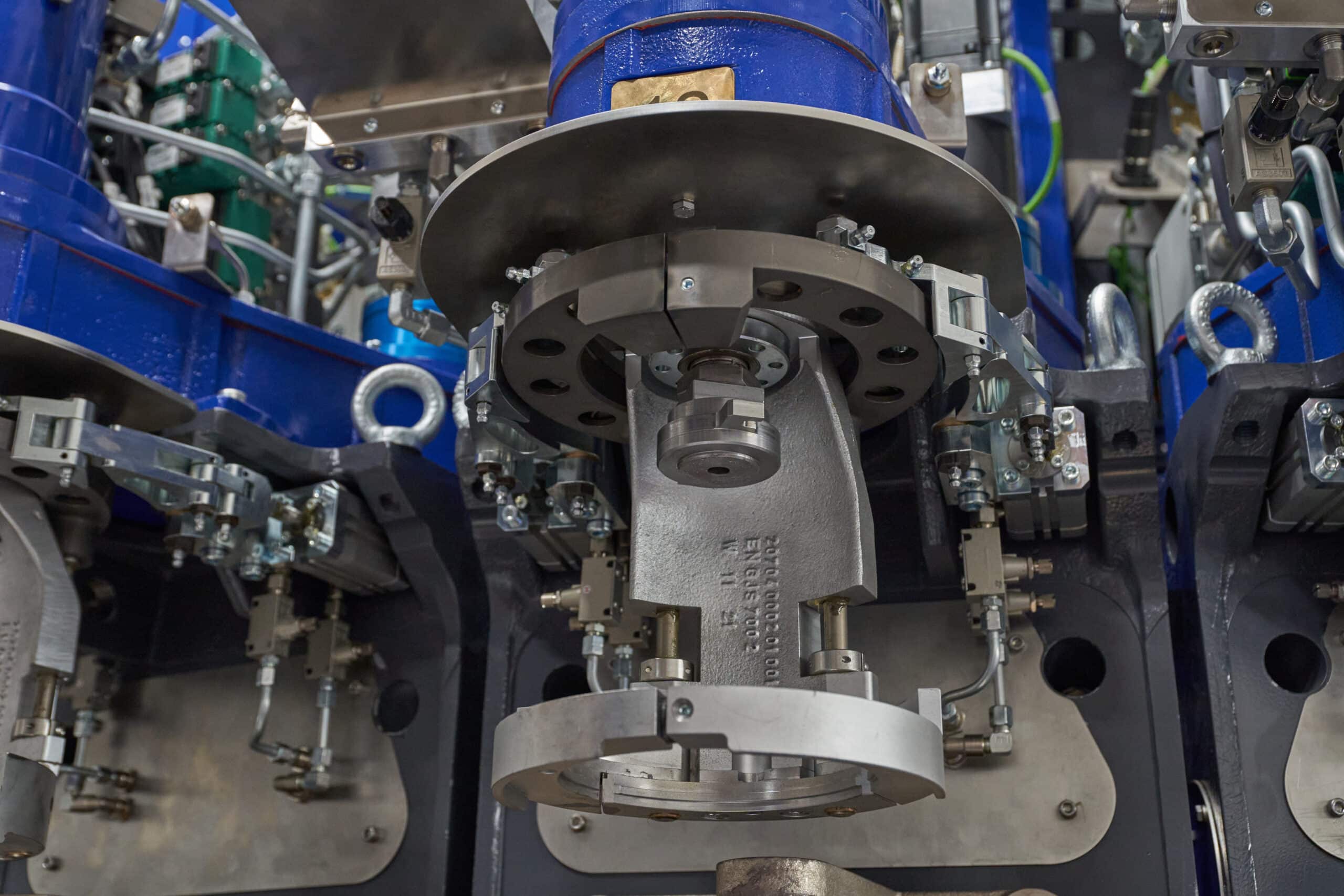

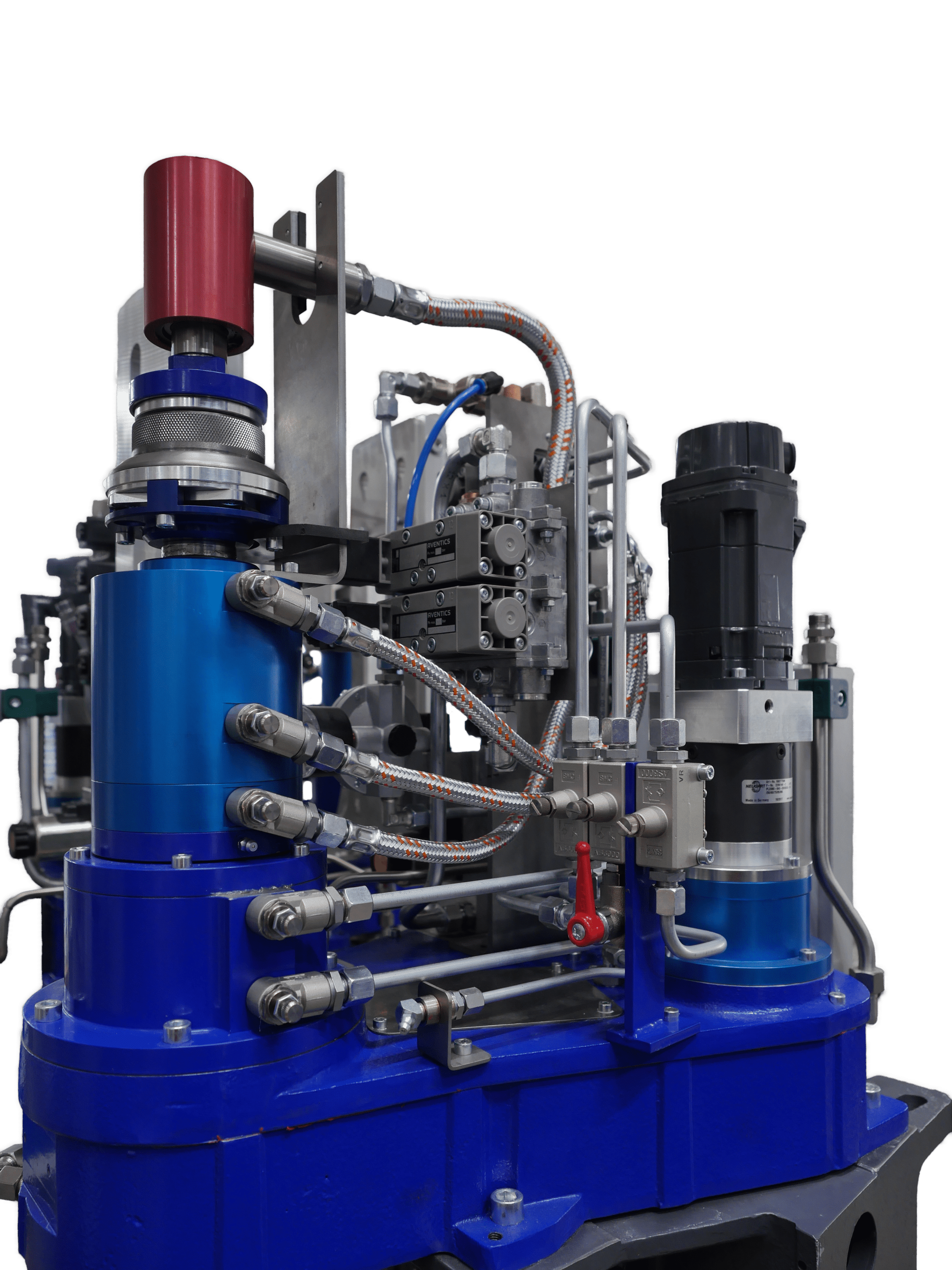

- ✓ pre-press-unit (pneumatic / hydraulic / servo pressing) with reduced moil weight

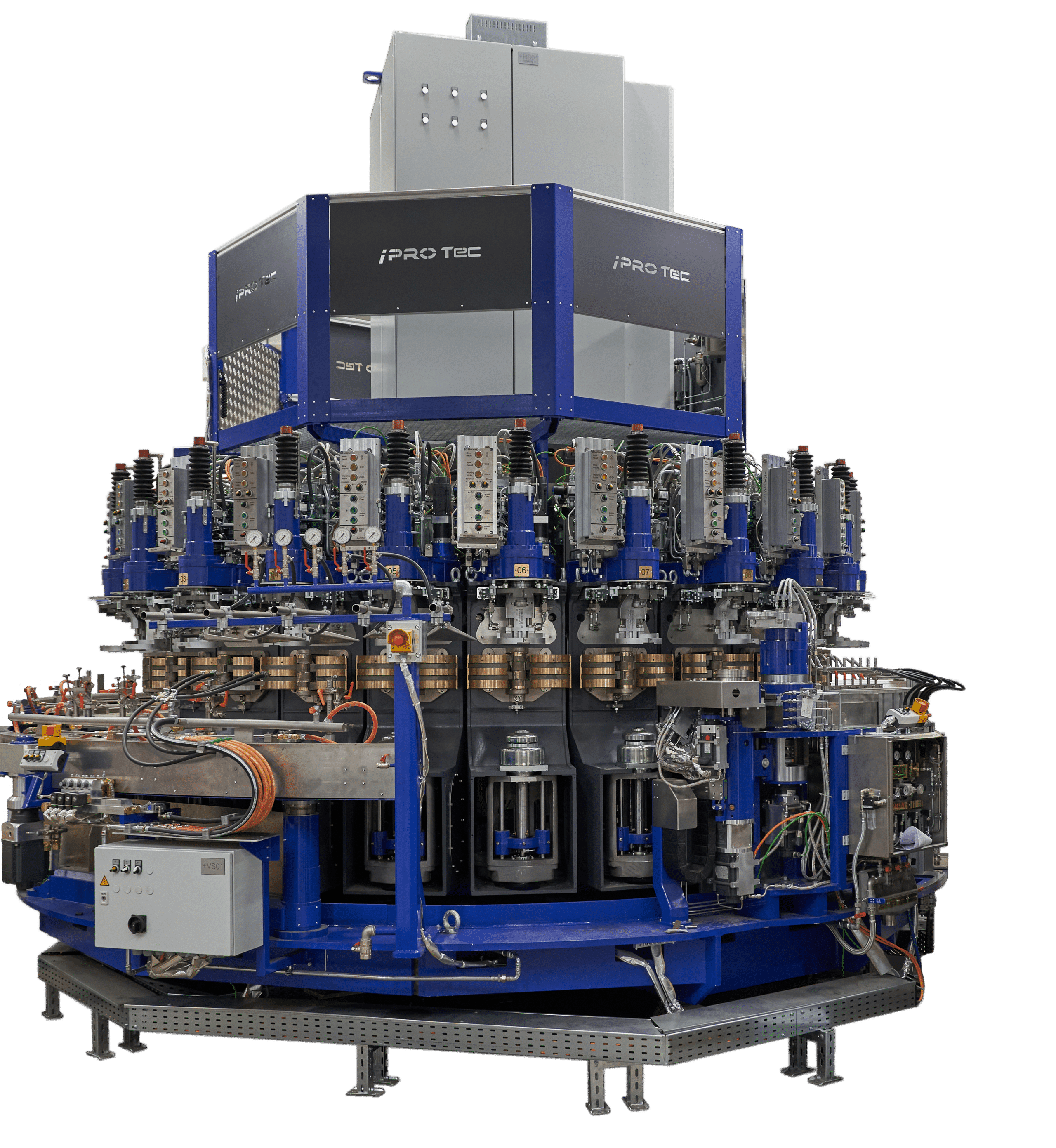

- ✓ from 1 to 32 stations

- ✓ modular station concept for quick exchange

- ✓ divided working table (two or three parts mould equipment)

- ✓ substations with independent servo drive for each station

- ✓ burner tracking system for highest product quality and low energy consumption

- ✓ rotary take-out system with modular concept

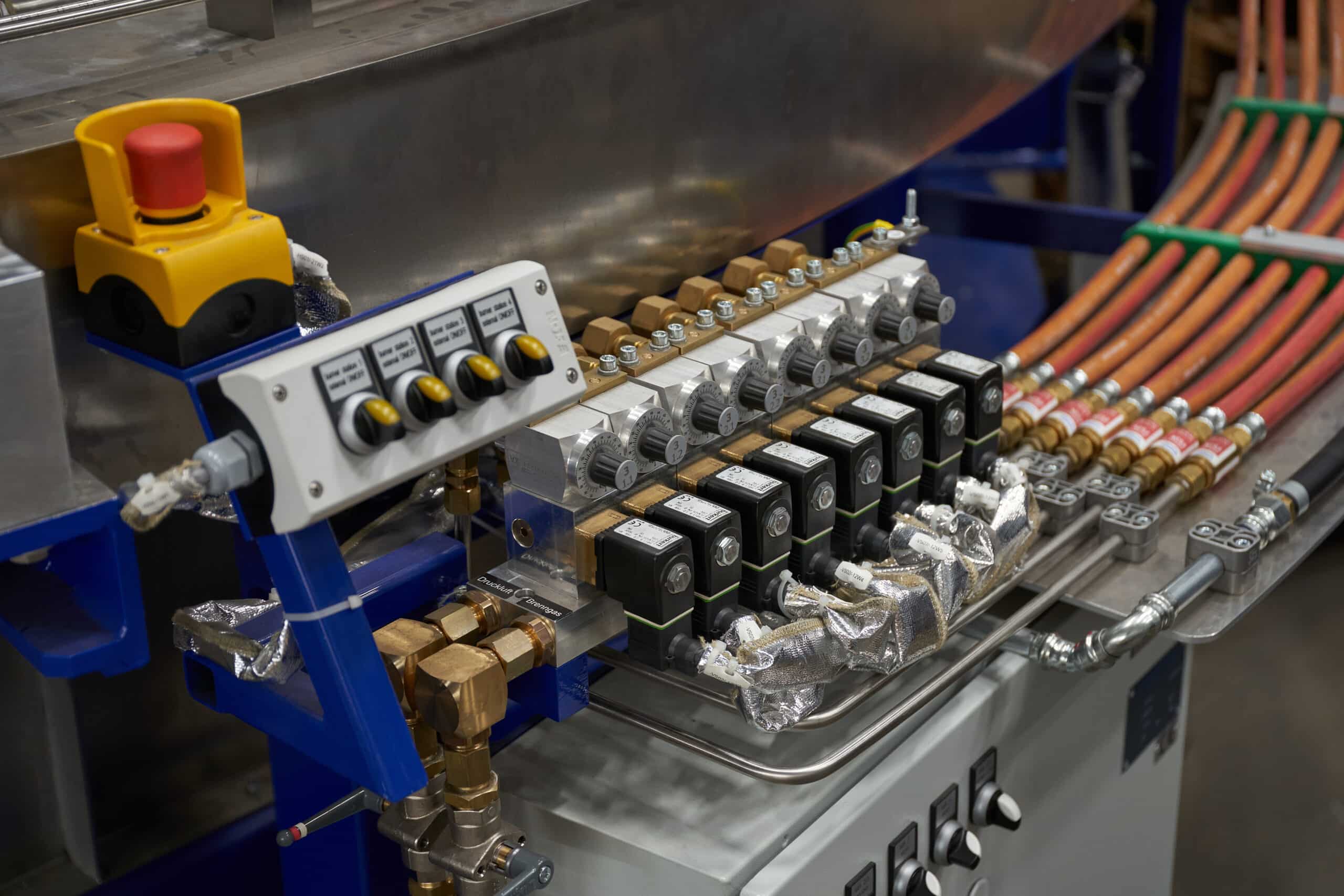

- ✓ SIEMENS control system with high efficiency servo drives

- ✓ precise digital control of all the devices

- ✓ operator friendly

- ✓ maximum reliability

- ✓ easy and fast job change

- ✓ configuration for tumbler, stemware, vases The long-term partnership with Zwiesel Glas has enabled IPROTEC to optimize and laboratory ware

Tobias Bredl

Your expert for Glassware Machinery

+49 9922 98 442

tobias.bredl@iprotec-gmbh.com