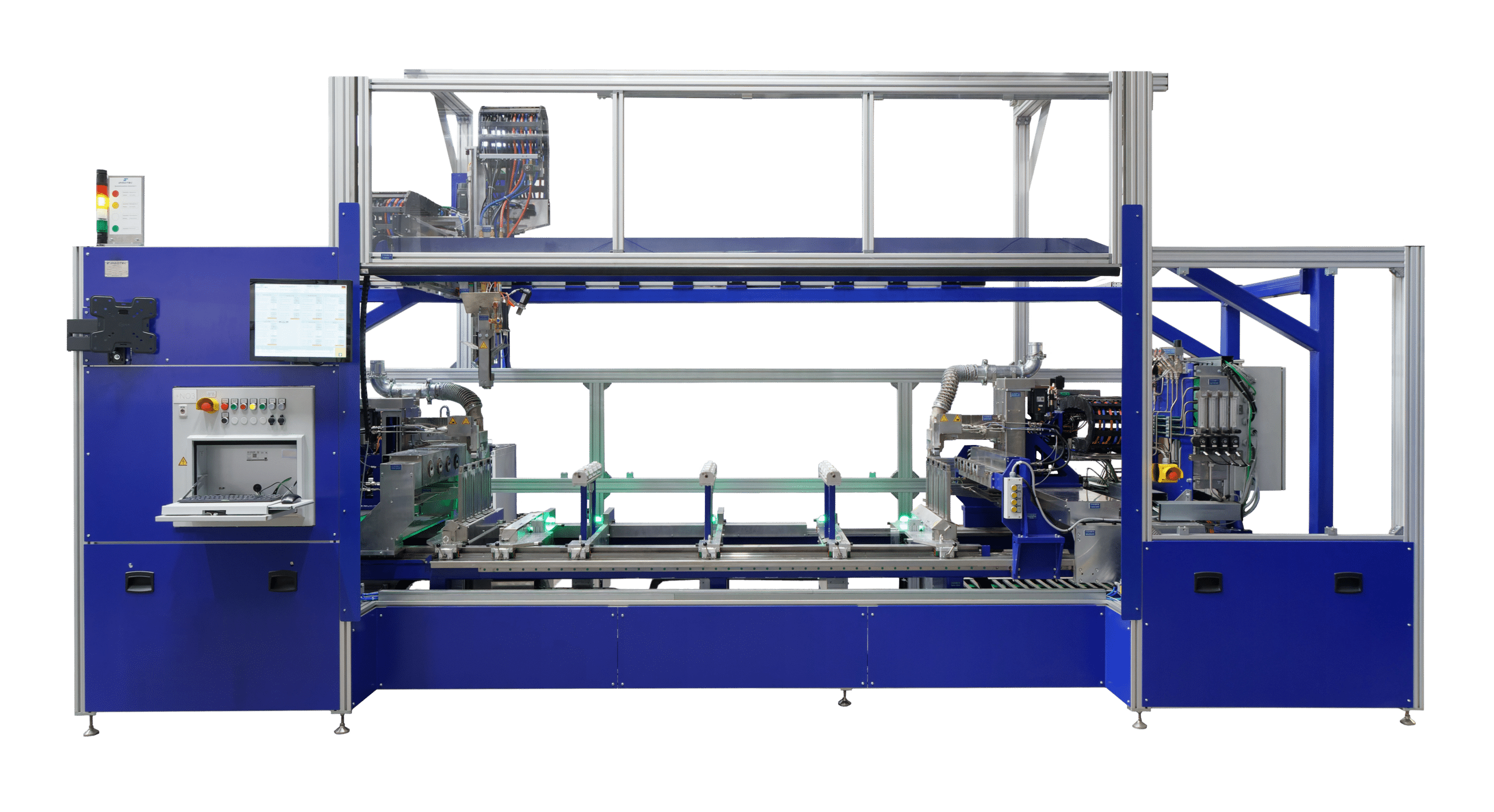

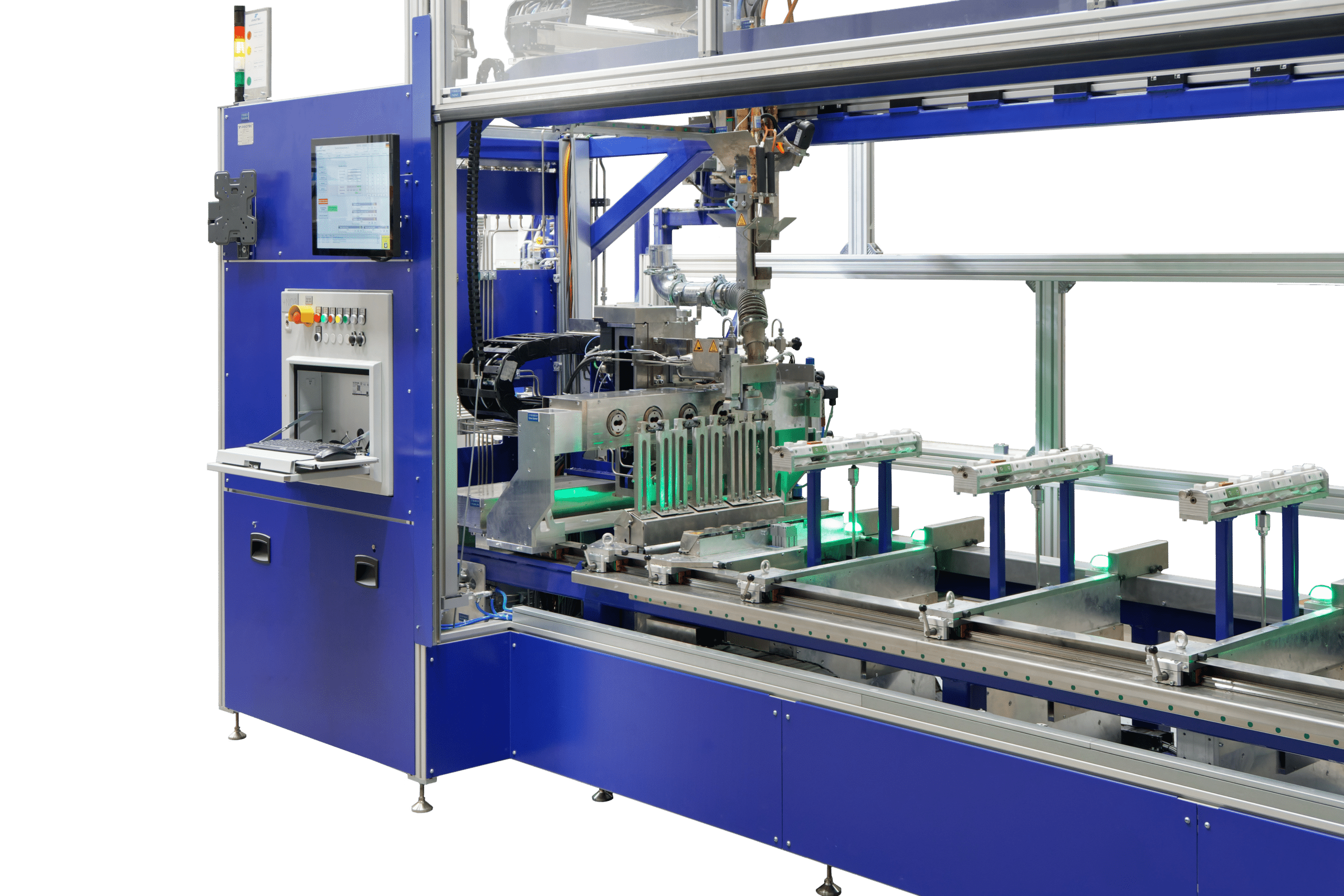

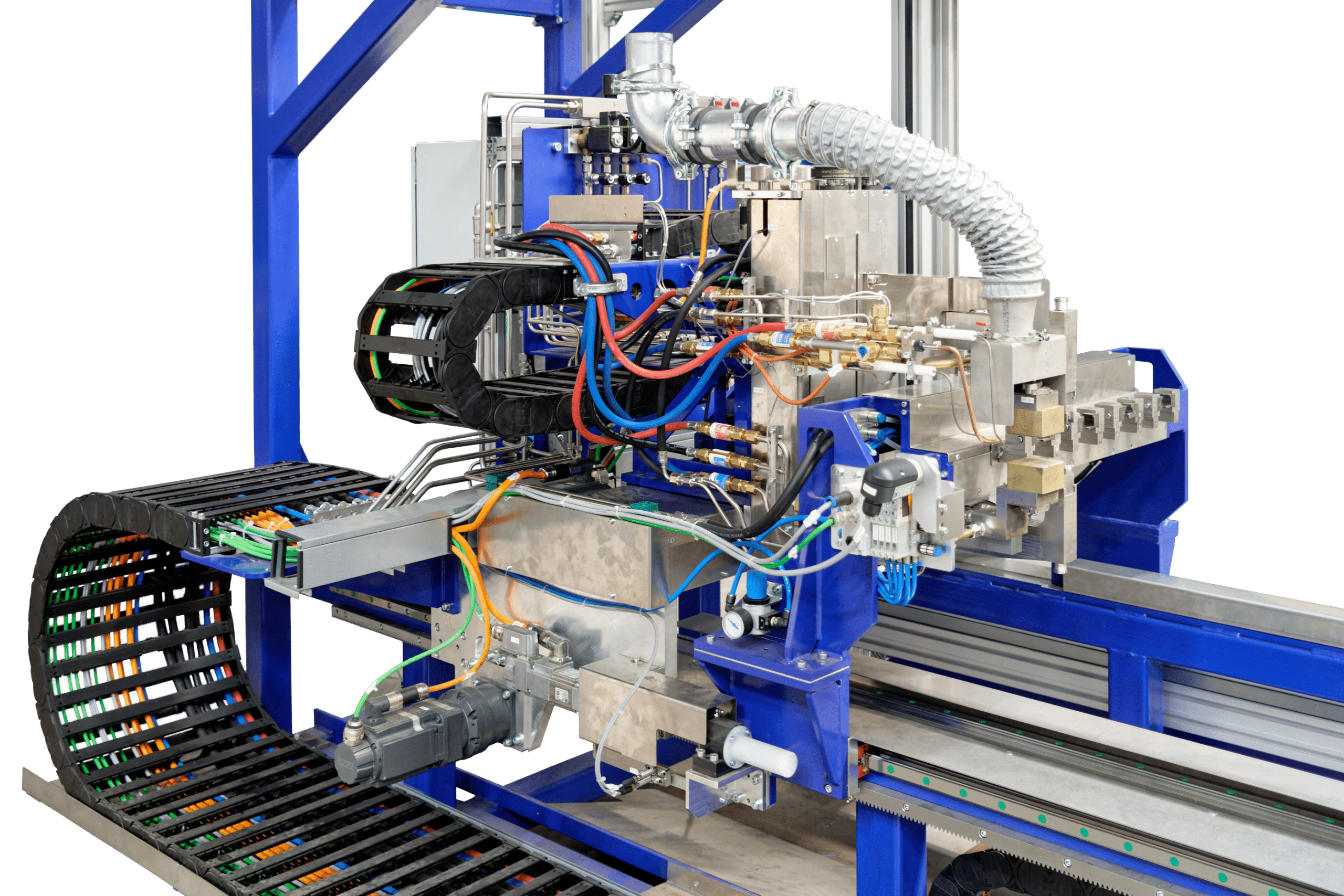

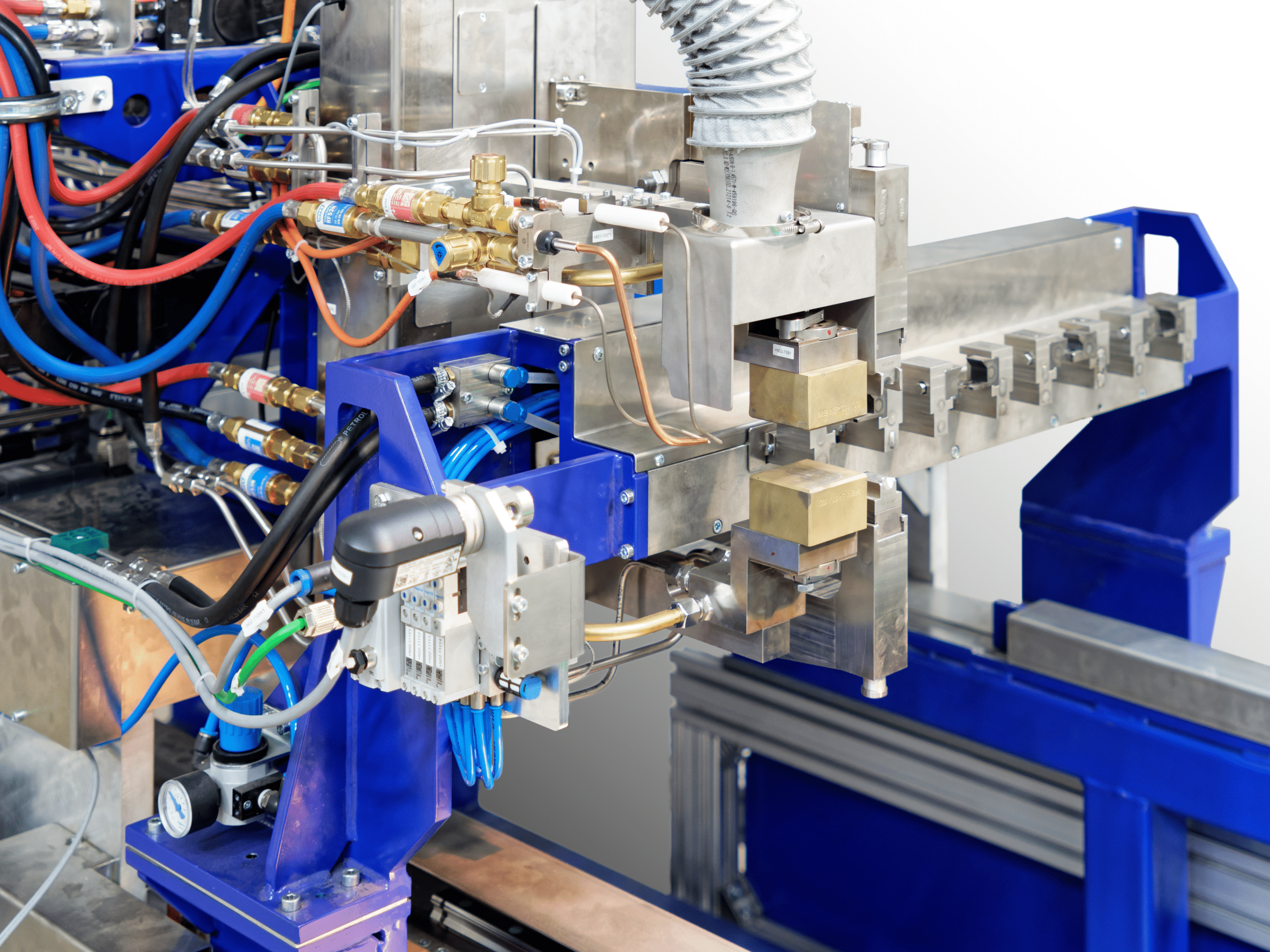

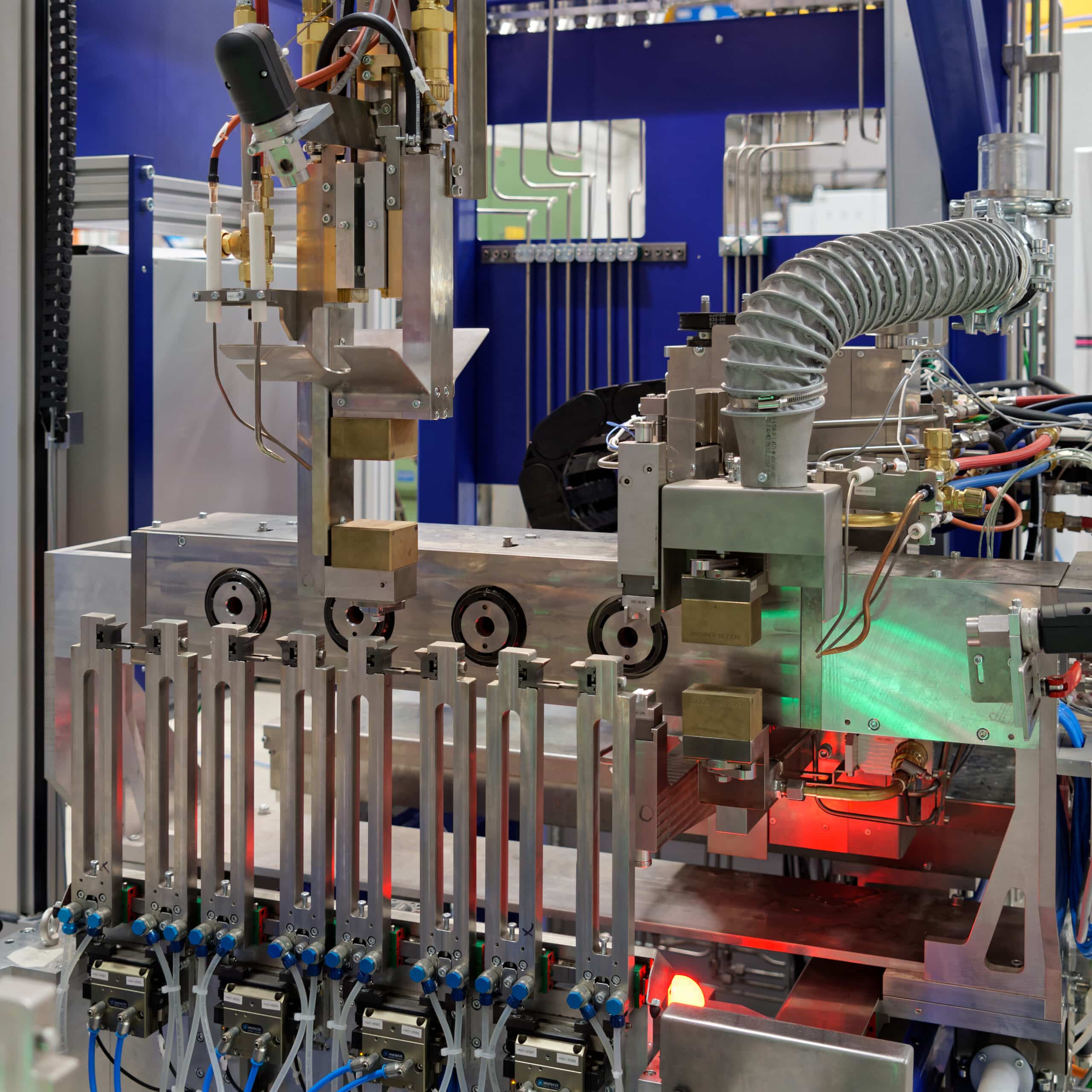

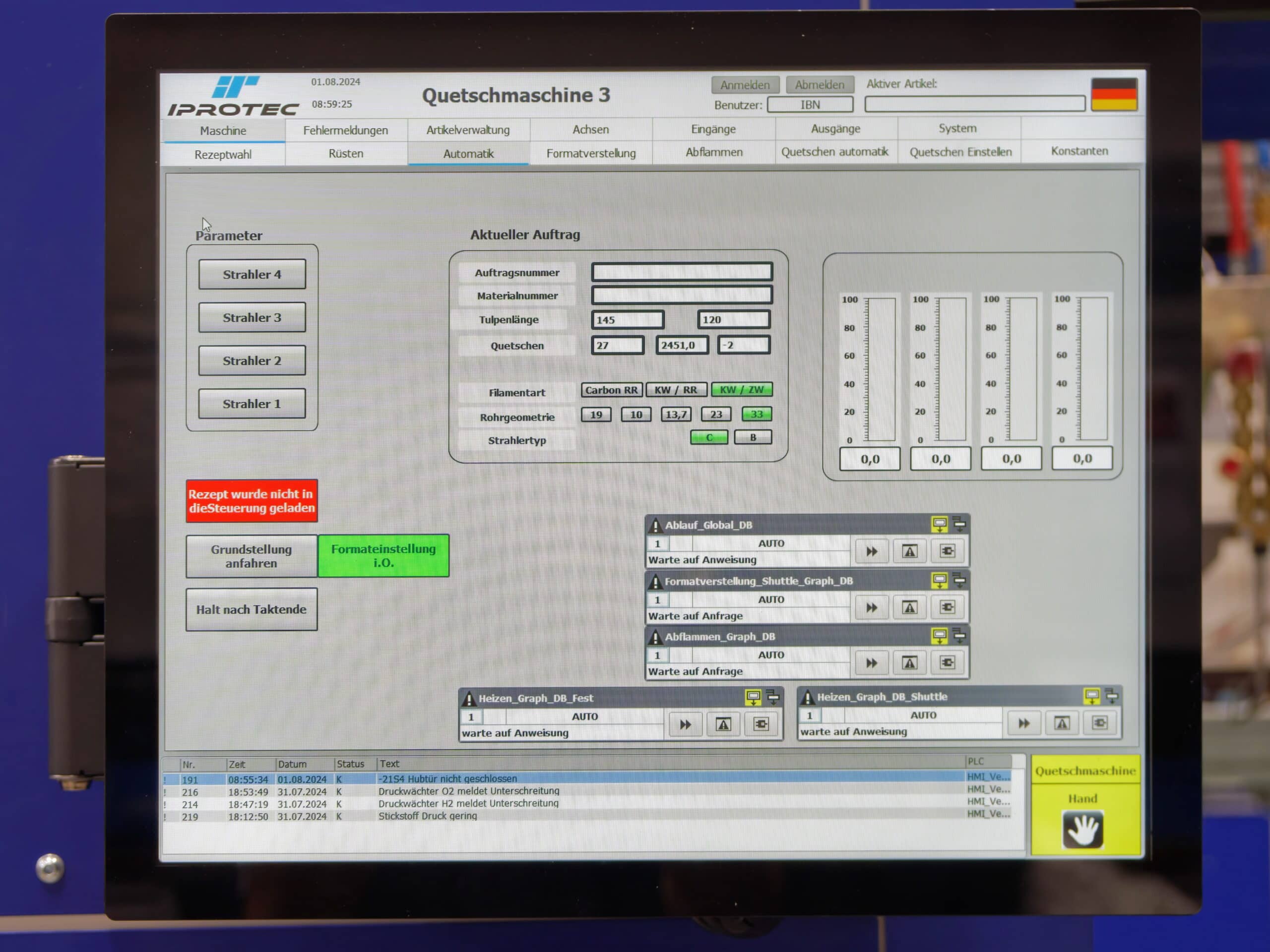

In the system, quartz glass tubes are joined with an IR heating wire and processed over a large diameter range. The tubes are flushed with a shielding gas and then welded on both sides. All adjustment variants are controlled item-specifically via servo drives and can be stored in a program database. During welding, the ends are crimped with a precisely reproducible force. During assembly, the correct component position is recorded and only then is processing permitted.

Stefan Vogl

Your expert for Special machinery

+49 9922 98 494

stefan.vogl@iprotec-gmbh.com