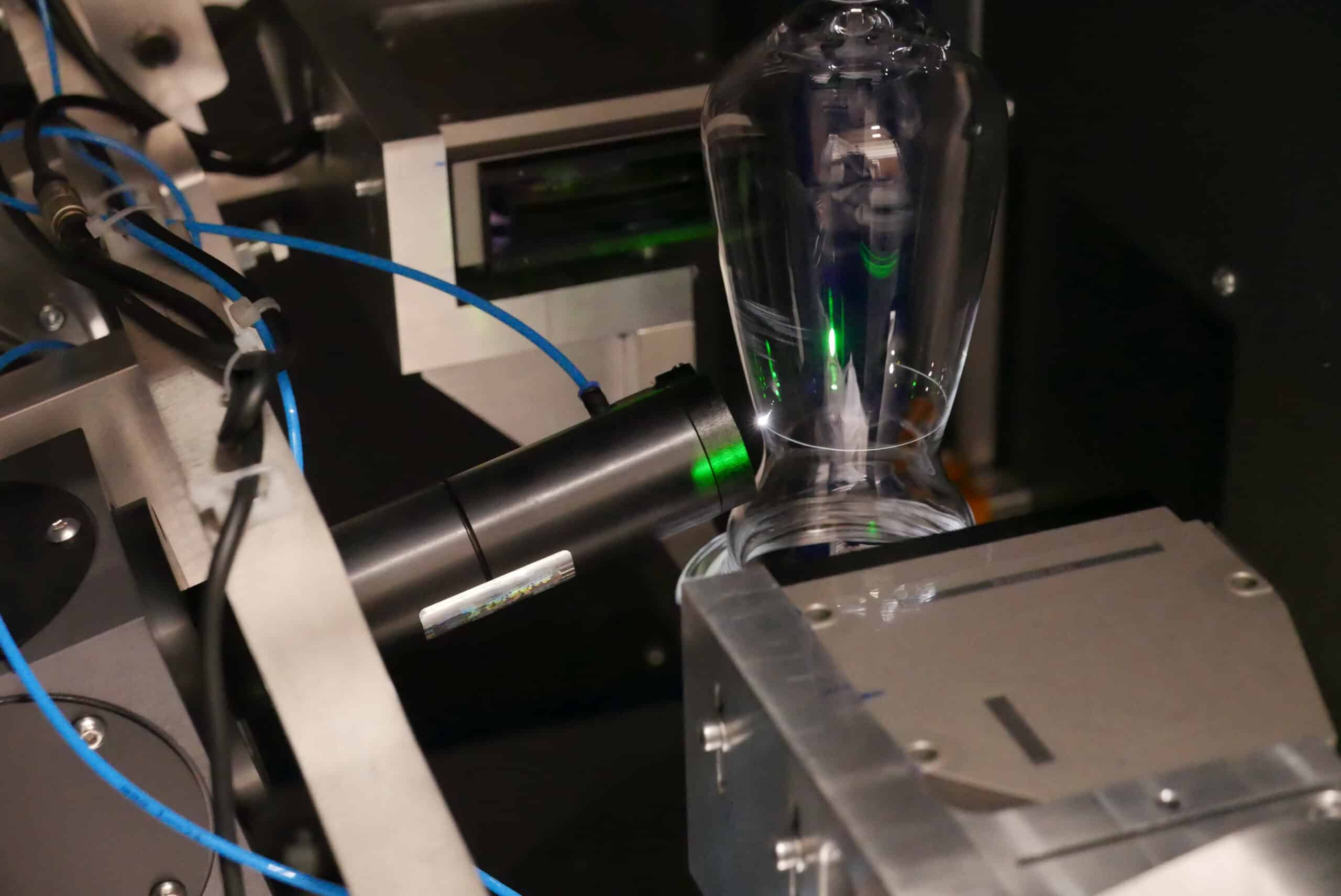

This newly developed process eliminates all the disadvantages of the traditional mechanical and thermal crack-off machines

with the result of best cutting quality and highest yields. The contactless cutting process makes the use of grinding tools as well as the downstream washing of the glasses obsolete and prevents mechanical and thermal stress in the glasses.

Technical Specifications

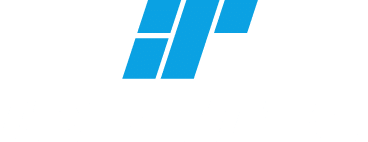

✓ fully integrated or stand-alone usage

✓ configuration for hot-end and cold-end

✓ modular design with single, double and triple station

✓ production speed up to 80 pcs/min

✓ cutting of wall thickness up to 2.6 mm in one revolution

✓ high performance torque motor drive for precise, fast and maintenance free indexing

✓ servo driven linear loading / unloading units with

gripper head / vacuum cups

✓ power efficient ultra-short-pulse-laser-system

(50 Watt power – 1064 nm wavelength)

Advantages

- ✓ non-sensitive process regarding wall thickness distribution, ovality, bent glasses

- ✓ no condensation (no thermal cutting process)

- ✓ no additional tempering for process required

- ✓ no grinding / water usage needed

- ✓ contactless process (no thermal / mechanical stress) with high yields

- ✓ highest rim quality (no chipping / no micro cracks)

- ✓ reduced energy consumption required for rim glazing after cutting

- ✓ reduced operation / maintenance costs compared to CO2-Laser / burn-off machine

- ✓ maximum process stability and repeatability